We live in a global marketplace. A marketplace where you can get your hands on anything from anywhere. A marketplace where someone’s always offering a better deal. If that is the case, why would you do things any differently? Because one aspect of sustainability is supporting your local community and maintaining or growing it for future generations.

Why source materials locally?

1. Using locally manufactured materials can greatly reduce your carbon footprint.

This is a simple concept. The less traveling your product has to do, the less fossil fuels are burned resulting in less harmful emissions released into our atmosphere. Where possible, when designing a commercial space, we spec locally-available materials.

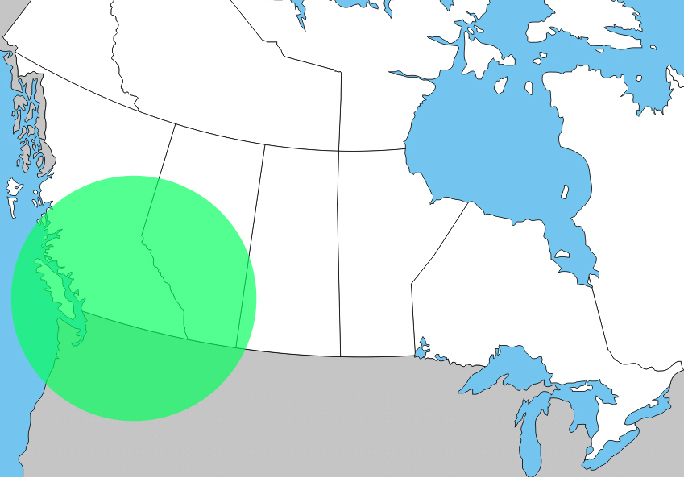

An 800km radius from our office meets LEED’s requirements for locally manufactured materials. Read on to learn more.

2. Sourcing locally manufactured materials supports your community.

Supporting your local manufacturers, whatever the product may be, helps the local economy and keeps money within the community. This in turn contributes to the future success of your regional area. Supporting the smaller operations who are there to serve your region specifically allows the mom and pop shops to continue doing business against the big box and online stores.

3. Personal attention.

Ok, so we all know how easy ordering products online has become. And the prices attached to those items coming from all over the world can be a great deal less than purchasing from someone who actually makes the product locally. But what happens when you have a problem with that product? Is someone going to fly to your place of business the next day to take a look, fix the problem or replace the product with a new one they brought along just in case? Nope.

One of the beautiful things about working with the local manufacturers is their proximity and availability when you need them.

4. Leadership in Energy and Environmental Design (LEED) accreditation

If your project is going for LEED accreditation you will gain valuable points by sourcing materials locally. The definition of local as far as LEED is concerned is 500 miles, or just over 800 kilometers. In order to gain the various points available the material or product must be extracted, processed and manufactured within this radius.

LEED ID+C is active in promoting green design in Canada. One of the programs they run is LEED which promotes a whole-building approach to sustainability.

How to source materials locally?

1. Talk to people around you in the community.

Talking with your neighbours, business colleagues and friends is a great way to learn about potential manufacturers in your community. You can also ask the local manufacturers you have met or are considering to source from who they know, chances are that they will be able to recommend other local contacts.

2. Attend local networking events.

Networking events are another excellent way to meet or learn about your local manufacturers. Going to a regularly scheduled, well attended, well established networking event will provide you with direct contact or recommendation to that specific material or product you are looking for.

3. Yellowpages.

Not everyone uses the phonebook these days, but you can find the same information online. Whether you are flipping through the Yellowpages old school style or using the internet, the Yellowpages continue to be an excellent resource to find any business in your area.

4. Look to the past.

Take a walking trip around your area and pay close attention to the older buildings. The materials you see used on and in them were most likely sourced locally and should give you an idea of the types of materials you should be able to find manufactured in and around your community.

Kelowna’s Laurel Packing House was completed in 1918. The interior boasts beautiful old wood timber and floors.

5. Word of mouth.

Word of mouth is a powerful tool, so if you have had a great experience with a local manufacturer please ensure to pass that information on to anyone interested. Share your amazing contact with other designers in your area, your friends and colleagues, and be sure to write a shining testimonial for the owners to show off. This is another way that you can help on the sustainability front.

Over the next few posts we will be showcasing some local manufacturers who we have learned about and worked with over the years.

» Want to know more about how to support your local community for your commercial Interior Design project? Contact Hatch Interior Design located in Kelowna, British Columbia – Sustainable Interior Solutions for the Modern Workplace.